Nonetheless, it’s imperative that you Be aware that epoxy repairs will not be as extended-lasting or trustworthy as soldered repairs and will be thought to be A short lived Answer.

Clear The placement in the leak comprehensively. Scrape rust together with other particles away if necessary, and ensure any grease, grime, or debris is eliminated with a rag plus a solvent if demanded.

Do this continuously until finally a black tarry shit begins to bubble off on the brass. It can take a handful of heating / fluxing cycles. Once the black shit floats absent go on heating and use the solder. The solder need to move out clean and shiney!

Just before soldering, be sure the surfaces to become joined are clean up and no cost from dirt, corrosion, and old solder. Use wonderful sandpaper or maybe a wire brush to remove any impurities.

Last but not least will come time for the final checking stage! To do this effectively with no harmful possibly steel included (aluminum and copper), Be sure that you take a look at out joint energy by implementing slight strain on to them in an effort to guarantee no weak points exist within just their link place right before declaring The work done productively!

Radiators can build leaks eventually, and When you have a radiator that needs to be fixed for The instant but can’t await a long-expression resolve, you will have to quickly handle it. The good news is, this can be carried out in a number of means:

Before soldering a radiator, careful preparing have to be accomplished to make certain the best possible repair. Start out by draining the coolant through the radiator after which rinse the unit comprehensively with warm water. Fork out Particular interest into the regions that are going to be soldered, as they must be totally clean up.

It is necessary to adhere to these ways in the well timed uninterrupted 1-two-3… sequence. Normally, the address strong oxide coating can reform and hinder the solder bond. So, ensure that you have all your equipment and materials staged and ready to go before you decide to start out.

Every thing that you've must operate wonderful. If the very best tank is brass, it should be straightforward peasy with a superb cleaning prep. If the top tank is steel, it might choose a lot more care In the event the surface area requirements tinning:

Precision is vital: When making use of solder and flux, accuracy is significant. A steady hand and thorough application will be certain a neat and effective bond. Prevent applying too much heat which will melt the realm around the joint or make weak places during the solder bond.

I've an outdated brass radiator. It designed a pinhole inside the header tank right now. I rigged up a pressure tester and pressurized the tank to fifteen kilos and it held so I am not concerned about functioning noticeably considerably less strain and beginning another leak.

Ultimately, apply flux designed for use with hot-dip soldering before heating up your equipment. Flux helps reduce oxidation within your solder joint and permits an ideal bond in between metals with out creating excessive warmth.

is vital for best adhesion. Use click over here great sandpaper or perhaps a wire brush to get rid of any Filth, corrosion, or aged solder from the area to become soldered. This assures a cleanse and sleek area for the solder to adhere to.

These solders frequently contain a flux to aid during the soldering system. Many thanks! We're glad this was helpful.

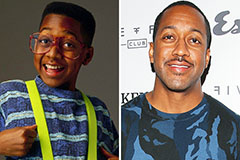

Jaleel White Then & Now!

Jaleel White Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!